Wago

Wago is a top manufacturer of electrical components, automation and interface electronic technologies. For 60 years, our company has created simple, fast and smart tools such as innovative cabling components for use in highly demanding systems. We strive to be a reliable foundation for safer, stronger, and more efficient connections.

Products

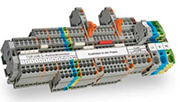

Terminal Blocks

WAGO's TOPJOB® S Rail-Mount Terminal Blocks offer three ways to wire: lever, push-button and operating slot. The comprehensive line of through and function terminal blocks for conductor cross-sections from 0.14 to 25 mm2(26–4 AWG) offers a variety of advantages. With push-in termination of solid and stranded conductors, as well as fine-stranded conductors with ferrules, TOPJOB S offers a single rail-mount terminal block system for virtually any application in the world. TOPJOB® S Through Terminal Blocks are available as single-, double- and triple-deck versions, as well as quadruple-deck terminal block.

Power Supplies

WAGO's efficient power supplies always deliver a constant supply voltage – whether it's for simple applications or for automation with greater power requirements. WAGO's compact, high-performance power supplies in DIN-rail-mount housings offer solutions to a wide variety of applications.

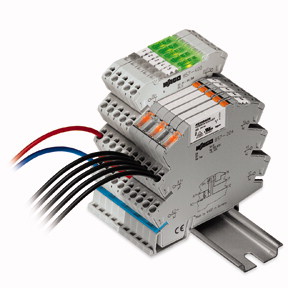

Interface Modules

Modern equipment design requires multiple components that can meet diverse challenges: User- and maintenance-friendly, limited budgets, safety and availability, simplicity in design and usage. These demands are more than satisfied by the different WAGO interface modules in their various designs, such as pluggable function and interface modules, narrow relay and optocoupler modules and modern, high-efficiency switch mode power supplies. Benefits of WAGO interface modules:

- The components are pluggable - reducing installation time.

- Exchange or adjust components easily and trouble-free.

- Reduce costs and compact design with smaller optocouplers and relay modules.

- Fewer errors during commissioning using an interface module with standard interfaces.

Terminal Block Connectors

Whether it is for terminating solid conductors with one another or solid, stranded and fine-stranded conductors together, WAGO has the right connector to meet your most varying requirements.

From the original WAGO 273 Series PUSH WIRE® connector for junction boxes to the WINSTA® connectors for the building installation, WAGO offers a comprehensive range of electrical interconnection products based on innovative Spring Pressure Termination Technology. Only these clamping and connecting systems can guarantee proper functioning and 100% reliability and all that without any maintenance.

Ethernet Switches

WAGO’s industrial switches feature a redundant power supply and switchable ring redundancy providing uninterruptible data communication. With a short recovery time of under 20 ms, the Xpress Ring increases your process reliability. The productivity and network availability of your machines and systems is always ensured. In addition to communication link redundancy, a redundant power supply – which can also be monitored using an alarm relay – is integrated into the switches.

Programmable Controllers

Industrial I/O Modules

For optimal automation both inside and outside the control cabinet: the flexible IP20 and IP67 remote I/O systems for all applications and environments. Fieldbus-independent: Compatible with all standard fieldbus protocols and ETHERNET standards. Wide variety of I/O modules available for nearly every application, as well as extensive range of accessories for marking and connection technology.