Universal Robots

Universal Robots is a leading innovator in the field of industrial automation and easy-to-use robotic systems. Our mission is to empower change in the way work is done using our leading-edge robotics platform. We strive to produce groundbreaking technologies that move people, industries, and the world forward.

Products

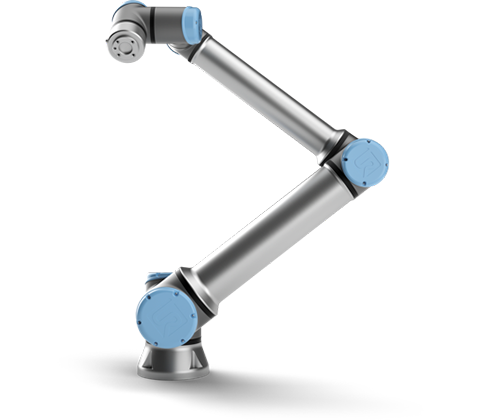

Robot Arms

UR3e

Small but powerful, the UR3e has a payload of 3kgs and reach radius of 500mm. With 360 degree rotation on all wrist joints and infinite rotation on the end joint, this table-top cobot handles high precision tasks and light assembly tasks with ease.

UR7e

Universal Robots’ popular UR5e just got a 2.5 kg payload upgrade. Introducing the UR7e!

The UR7e industrial collaborative robot brings ultimate flexibility to medium-duty applications with a payload capacity of up to 16 pounds and a reach of 33.5 inches, that’s over 7 inches further than the average worker’s arm! This substantial range is ideal when parts need to be loaded into a machine or tasks need to be completed outside of the reach of your employees.

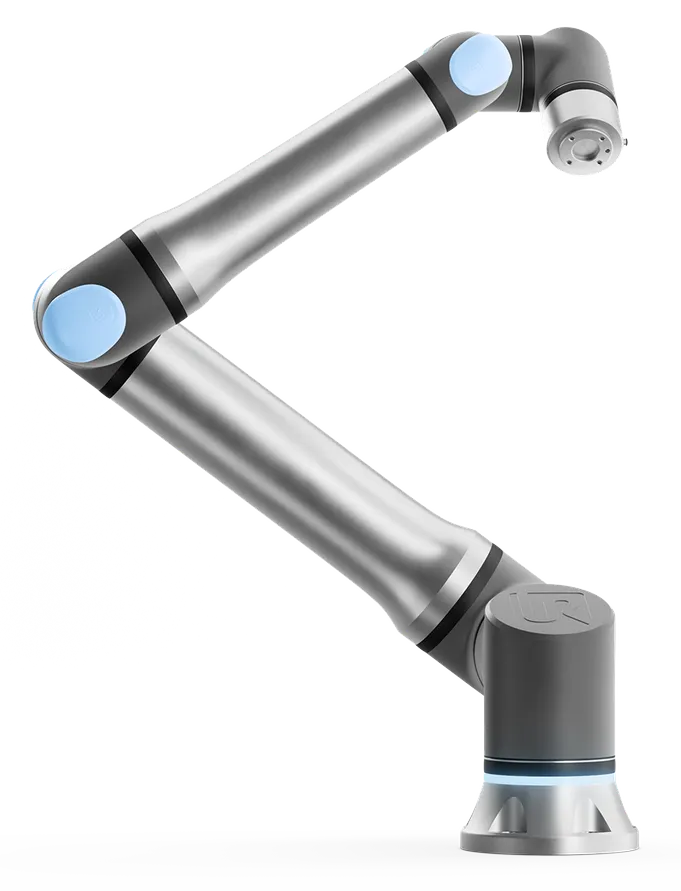

UR12e

The most popular of Universal Robots line of industrial, collaborative robots, the UR12e is ideal for Palletizing, Machine Tending & Welding applications. Extraordinarily versatile, this cobot delivers both a high payload lift of 27.55 pounds and a long reach of 51 inches. This combination lends the UR12e to endless automation possibilities.

UR15

Meet the UR15, Universal Robots sharper, faster, more agile cobot. The UR15 is the most lightweight member of the UR Series offering speed and dependability that easily fits in a variety of environments.

Lightweight yet remarkably strong, the UR15 breezes through intensive workloads with the smoothest motion performance thanks to URs’ OptiMove.

Powered by Polyscope X, the UR15 is ready for AI to enable seamless integration and usability combined with future ready scalability.

UR16e

UR16e delivers an impressive 16kg (35.3 lbs.) of payload an 900mm reach within a small footprint, and is ideal for use in heavy machine tending, material handling, packaging, and screw and nut driving applications. This powerhouse robot allows for heavier end of arm tooling and multi-part handling, and is especially useful for achieving shorter cycle times.

UR8 Long

Universal Robot’s all-new UR8 Long is engineered with precision to extend your reach further and optimize every cycle.

With a reach of 1750 mm (68.9 in) in a compact, lightweight design, the UR8 Long is ideal for welding, pick & place and quality inspection. A smaller wrist allows this cobot to fit into tight setups and tackle tasks that larger traditional arms can’t.

The UR8 Long excels in applications requiring precise linear motion and high-speed acceleration. Accurate torque control and advanced joint architecture make this the ideal cobot for jobs demanding both reach and precision.

UR20

The UR20 is built for higher payloads, faster speeds, and superior motion control all within a lightweight, small footprint system for optimal versatility within your existing production space. No special electrical hookups or costly wiring solutions are required. Even with the big step up in performance, a single-phase standard power outlet is all that’s needed to power the UR20.

With a 1750 mm reach and 25 kg payload capacity, UR’s next generation cobot handles more tasks, fits more applications, and assists in more environments than ever before.

UR30

The UR30 can lift heavy payloads while maintaining a compact footprint in a collaborative setting. With a 30 kg lifting capacity and a 1300 mm reach this robot can tend larger machines, palletize heavy products, and effectively support high torque screw driving.

Building off the same architecture as the UR20, the UR30 offers extraordinary lift in a compact footprint with superior motion control ensuring the perfect placement of large payloads. With the ability to handle higher torque, the UR30 opens the door for precise screw driving and the 35 kg payload brings productivity to everything from machine tending with multiple grippers to palletizing heavy parts.

Solutions

UR+ Solutions

Universal Robots+ is an online showroom that provides cutting-edge products to customize a UR robot application that perfectly meets your requirements. Streamline deployment for the most popular cobot applications by combining multiple components with software designed on the UR+ platform.

End-Effectors

The Hand-E Gripper allows you to start production faster. Its Plug + Play integration adapts quickly to parts of various shapes and sizes and is suited for a variety of different applications.

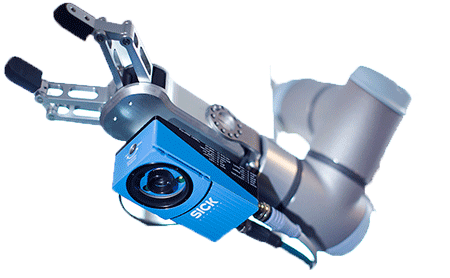

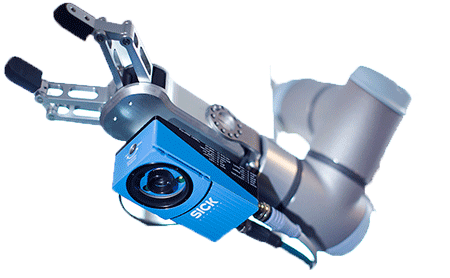

Robot Guidance

Create a vision guided robot application in minutes with SICK 2D vision! The SICK Inspector URCap software provides an easy integration between the Universal Robot and a SICK Inspector PIM60 2D vision sensor.

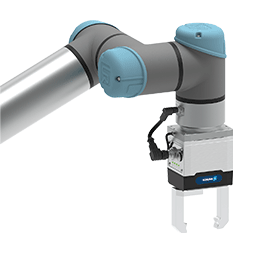

Gripper Integraton

SCHUNK versatile 2-finger gripper available in three sizes for small components for maximum workpiece variety with maximum process reliability for flexible handling of printed circuit boards in electronics manufacturing, sample and tray handling in laboratory automation, and universal workpiece handling.

Robot Guidance with SICK Inspector

Create a vision guided robot application in minutes with SICK 2D vision!

The SICK Inspector URCap software provides an easy integration between the Universal Robot and a SICK Inspector PIM60 vision sensor.

View the live image from the sensor, calibrate and align the sensor, choose reference object and get pick-point positions, all from the Universal Robot's teach pendant. In addition to outputting pick-points in the robot's coordinate system, the Inspector PIM60 enables inspection and measurement tasks for pass/fail-criteria or trending.

- Screwdriving

- Pick and Place

- CNC

- Packaging and Palletizing

- Quality Inspection

- Lab Analysis and Testing

- Machine Tending

AI Accelerator

The AI Accelerator is the perfect way to add artificial intelligence to your robotics solutions. The AI Accelerator offers endless possibilities to improve modern production. From improved decision making through computer vision to enhanced motion capabilities derived from training models.

What's in the box:

- Embedded NVIDIA Jetson Orin AGX 64GB compute box

- Orbbec Gemini 335Lg - 3D Vision camera

- Camera bracket & flange extender

- Cabling & cable guidance

- Flyer & manual

- USB cable (GMSL soon)