Tolomatic - Switch to Electric Actuators

If you’re struggling with your pneumatic or hydraulic automated system, you may want to consider electromechanical actuation. Not only does this technology deliver better precision, flexibility and reliability than traditional pneumatic and hydraulic technologies, but modern electromechanical actuators also meet high-force requirements.

While hydraulics and pneumatics have their place — for example, if your application requires top-tier power density — sometimes the drawbacks of these legacy workhorse technologies outweigh the advantages.

On the other hand, here are some of the challenges you won’t encounter with an electric system:

- Oil and air leaks

- Noisy power units

- Large and bulky footprint

- Manual changeovers

- Temperature fluctuation vulnerability

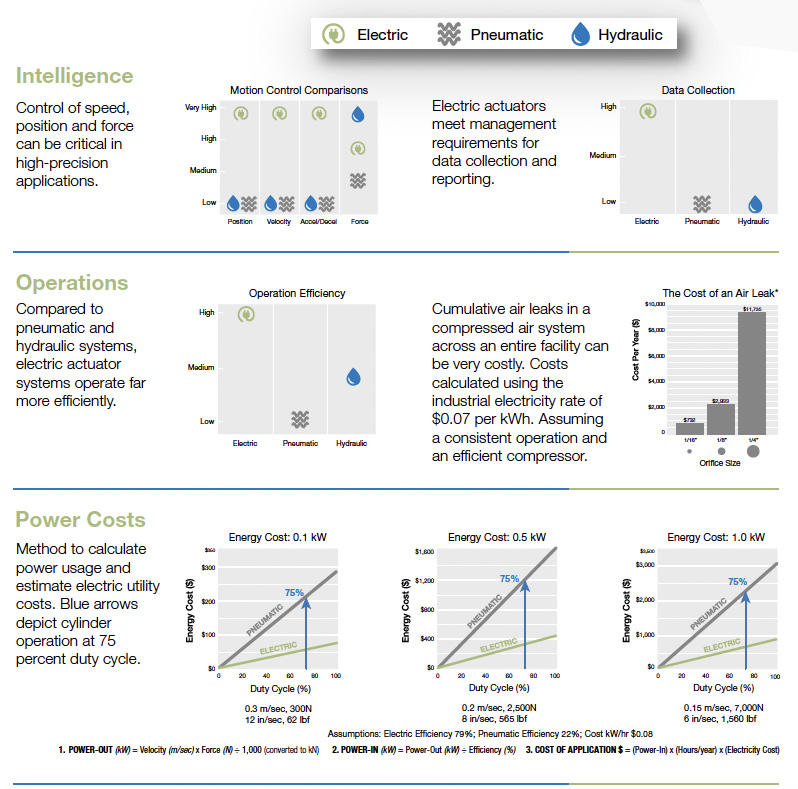

In addition to eliminating these complications, electromechanical actuators offer even more benefits. Electric components provide control flexibility that is unparalleled in pneumatic and hydraulic systems. Coupling an electric actuator with a servo drive and motor unlocks infinite control over all aspects of linear motion including speed, position and thrust.

Electric actuators are also extremely cost-effective, operating at around 75 to 80 percent energy efficiency. Including a servo in your electrical actuation system may initially be more expensive than traditional technologies, but increased efficiency and lower maintenance requirements will drastically reduce your total cost of ownership.

Comparing Intelligence and Operations

Electric vs. Pneumatic vs. Hydraulic Actuators

Tolomatic Electric Products: