SICK RFU61X

UHF transponder identification using a compact RFID read/write device for short sensing ranges

The RFU61x is the smallest read/write device in the UHF portfolio from SICK. It is perfectly suited for IoT applications directly on the workpiece or component. The RFU61x therefore rounds out the UHF product portfolio from SICK by enabling continuous identification along the entire value chain. The interfaces of the RFU61x enable direct connection of a trigger sensor, whereby the RFU61x can be used as a remote, self-supporting unit. Thanks to the integrated process logic, data can be processed directly in the RFU61x and passed onto the controller or IT systems. Like the other Ethernet-based RFU devices, the RFU61x can also be programmed according to individual requirements using the SICK AppSpace eco-system.

RFU61x AT A GLANCE

Benefits

Versatile application possibilities due to small size

Quick and low-cost installation thanks to direct connection option for trigger sensors

Very little programming work needed in the control thanks to process logics integrated in the device

Easy configuration through SOPAS ET saves time and costs for testing and commissioning

Simple connection with M12 cable for IO-Link variants

Depending on the device variant, SICK AppSpace offers a high level of flexibility when programming individualized software solutions

Rugged design for reliable operation, even in tough industrial environments

Features

Extremely compact design

Scanning range up to 0.5 m

Connection option for trigger sensors

Flexible interface concept (e.g. PROFINET, EtherNet/IPTM, OPC-UA, IO-Link (via IO-Link master)

Integrated antenna and data processing

Configuration via SOPAS ET

Ethernet-based variants: Compatible with SICK AppSpace

Rugged design (IP67)

ADVANTAGES

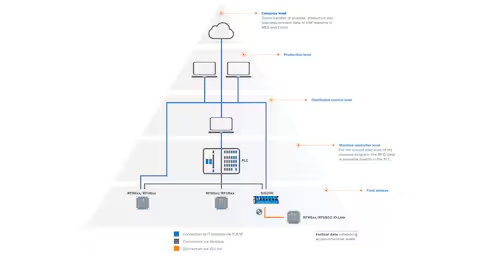

Complete transparency with the RFU family

Continuous and company-wide identification with a single technology is now possible for the first time. The RFU61x achieves complete transparency in production and logistics processes – from component assembly to the shipment of the end product. The foundation for this is UHF RFID technology: IIoT applications with scanning ranges of 0 to 10 m, bulk reading and resistance to interfering factors such as light, dirt and dust. A direct line of sight to the data card is also not required.

Continuous identification solution for production and logistics process

The RFU61x RFID read/write device, part of the RFID identification solutions from SICK, is allowing for full transparency along the entire value chain for the first time - and all with one technology

Intelligent UHF RFID identification in the smallest of spaces

The RFU61x is the smallest RFID read/write device of its type. It is optimally suited for IIoT applications for identifying workpieces or components. Diverse interfaces allow for the direct connection of trigger sensors. Intelligent data processing is already integrated. The RFU61x can therefore be used as a self-sufficient remote unit.

The RFU61x is optimally suited for applications with small installation spaces. Despite its compact dimensions, it offers the advantages of UHF technology.

The direct connection of a trigger sensor enables quick and easy commissioning.

The integrated process logic cleverly processes read data for all target systems from the control to the cloud.

The compact RFU61x is optimally suited for applications which do not offer much installation space. The sensor independently performs the triggering, reading and writing as well as processing of data.

IO-Link

SICK is a co-founder of IO-Link and offers a very broad range of IO-Link products. Together with many other sensors and actuators, identification solutions from SICK use IO-Link interfaces to generate and receive data and information that go beyond conventional switching signals or measured process parameters. Here you will learn how you can use different sensors combined with the IO-Link Master.

Your advantages at a glance

INCREASE SYSTEM PRODUCTIVITY

Integration of the sensors at the fieldbus level enables continuous communication up to the cloud. It also allows sensor data to be stored centrally and called up as needed, which is a good basis for increasing system productivity.

WIDE RANGE OF SOLUTIONS

The range of solutions from SICK includes many different devices with IO-Link. This enables a uniform communication infrastructure. In addition to the sensors, IO-Link Masters and other software from SICK also play a key role.

QUICK AND EASY DEVICE REPLACEMENT

Easy device exchange due to automated device identification: When using IO-Link devices in connection with the IO-Link Master, device parameters can be transmitted to replacement devices quickly and easily. Specially trained staff, additional tools or instructions are not required.