ROEQ Robotic Equipment

ROEQ produces specialized equipment for MiR (Mobile Industrial Robots). Their flexible logistics solutions are aimed to move you closer to a hands-free operation at your factory or facility.

Products

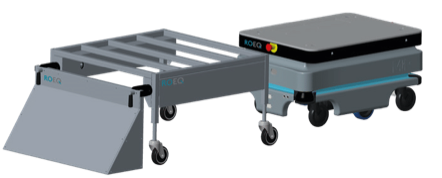

C300 Cart

The basic functionality is to use MiR100?/MiR200? with the Lifter Top Module to move goods between logistic points. The Lifter Top Module can be customized to support a variety of pallets and fixtures that are already a part of an existing assembly flow.

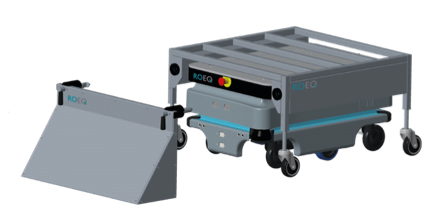

RB100 Rack Base

The ROEQ RB100 is made as a base, and can be used with a standard rack attached or as a base for a customized application. A MiR100?/MiR200? will align the RB100 Rack Base with its destination, which secures precision and stability in any work environment.

L150 Lifter

The basic functionality is to use MiR100?/MiR200? with the Lifter Top Module to move goods between logistic points. The Lifter Top Module can be customized to support a variety of pallets and fixtures that are already a part of an existing assembly flow.

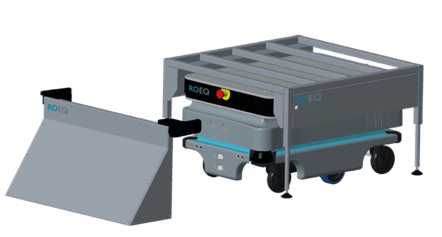

C300 Cart (Fixed)

The ROEQ C300 can be used as a permanently attached cart on a MiR robot. This application adds stability and enables increased payload. Furthermore, the system can utilize the docking facility if needed. The type of application can vary from a robot arm to a base for a conveyor belt ? and a lot of applications in between.

TB75 Top Belt

The basic functionality of TB75 is to perform automated load and unload operations, thereby making a MiR100/MiR200 able to carry out scheduled pick-up and delivery tasks.

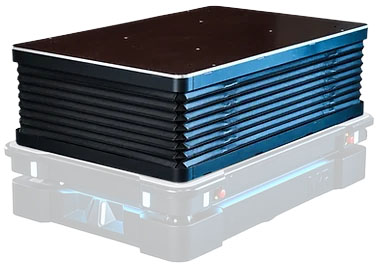

TR125 Top Roller

The basic functionality of the TR125 is to perform automated load and unload operations, thereby making a MiR100/MiR200 able to carry out scheduled pick-up and delivery tasks.

TR600 Top Roller

The ROEQ TR600 is a heavy duty top roller for MiR600 AMRs (Autonomous Mobile Robots). They can pick up and deliver heavy goods between conveyor stations and are ideal for transporting US, euro pallets and various cargo types

TML1200 Lifter

The ROEQ TR600 is a heavy duty top roller for MiR600 AMRs (Autonomous Mobile Robots). They can pick up and deliver heavy goods between conveyor stations and are ideal for transporting US, euro pallets and various cargo types

TR1000 Auto Top Roller

The ROEQ TR1000 Auto enables your MiR600 or MiR1350 AMR to transfer heavy goods between conveyor stations at different heights. The automatic height adjustments, with a large stroke – 240 mm/9.4” –gives the flexibility to adjust to your existing setup. Note the two package function, which allows you to pick up or drop off packages separately to two stations.

TR1150 Top Roller

The ROEQ TR1150 is a heavy duty top roller for MiR1150 AMRs (Autonomous Mobile Robots). They can pick up and deliver heavy goods between conveyor stations and are ideal for transporting US, euro pallets and various cargo types.

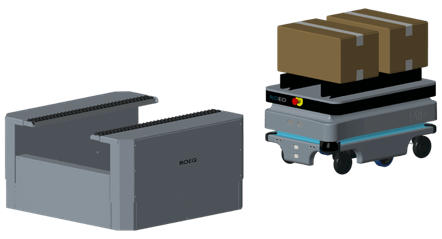

CP300 Cart Pallet

The basic functionality of the CP300 system is to perform automated internal pallet transport with the MiR100/MiR200. CP300 is designed to transport pallets, and with the special TMOZ (Top Module Oversized) the safety is incorporated into the design of the Top Module.

TR500 Top Roller

The TR500 is developed to support heavy internal logistics in industrial facilities. The basic functionality of the TR500 is to perform automated load and unload operations. The design enables safe and reliable transportation of goods with varying footprint. With TR500 the MiR500 is able to carry out scheduled pick-up and delivery tasks with many different types of heavy goods.