Robotiq

Robotiq designs and manufactures flexible robot grippers and complimentary components. We work with robot manufacturers, integrators and end-users to deliver dexterous grippers that enable new applications and improve productivity.

Products

2-Finger Adaptive Robot Gripper

The 2F-85 and 2F-140 Adaptive Grippers are the grippers for collaborative robots. Use them to accomplish a complete lineup of applications with a fast time-to-production—no robotics expertise required. They’re key to a highly flexible and reliable robotic cell.

Wrist Camera

The Robotiq Wrist Camera is designed to perform industrial applications with Universal Robots. Teach new parts and detect features quickly to ensure repeatable picking.

- Seamless integration with the Universal Robots wrist.

- Programming software that runs directly on the teach pendant.

- Three flexible multi-object teaching methods.

Hand-E Gripper

The latest product in Robotiq's line-up of Adaptive Grippers is Hand-E, the first UR+ electric gripper ready for the new e-Series generation of Universal Robots.

Hand-E’s high accuracy and 50 mm parallel stroke make it perfect for precision assembly tasks, while its sealed design ensures reliability in the toughest manufacturing conditions—including CNC machining. Hand-E’s design adheres to ISO/TS 15066 standard best practices, with maximum force, rounded edges, self-locking functionalities, and other features making it the gripper for collaborative robots.

Screwdriver Solution

Robotiq Screwdriving Solution is designed to fix changeover issues. Within five minutes, the solution can be reconfigured for alternate production. Providing consistent screwdriving around the clock, increasing throughput with a reliable and efficient solution.

Robotiq Screwdriving URCap simplifies programming, because it automates the force- sensing capabilities, as well as the communication between the screwdriver, screw feeder, robot, and vacuum technology.

Screwdriver solution includes:

- Robotiq Screwdriver SD-100

- Robotiq Screw Feeder SF-300

- Vacuum sleeves kit

- Screwdriver bits kit

- Robotiq Force Copilot license dongle

- Robotiq Screwdriving URCap (application software)

Vacuum Grippers

EPick and AirPick are vacuum gripper ready for use with the e-Series generation of robots from Universal Robots.

EPick operates without air supply, which makes it highly mobile. The EPick gets easily connected to the cobot wrist and needs no air supply.

PowerPick Grippers

Robotiq’s PowerPick gripper brings together the learnings from hundreds of palletizing applications. The PowerPick is very adaptable since it provides multiple handling configurations to pick a wide range of box sizes, shapes, and materials. It’s also robust in that it offers great reliability when exposed to less controlled conditions such as humidity and dust.

Robotiq’s PowerPick SingleCup is the most lightweight and compact cobot vacuum gripper for lifting small non-porous and porous parts. This vacuum gripper can handle a max payload of 6.5 kg (14.3 lbs) and can also operate in harsh environments. Provides more effective control of the high vacuum flow ensuring precision and reliability in every task.

3-Finger Adaptive Robot Gripper

The 3-Finger Gripper is the best option for maximum versatility and flexibility. It picks up any object of any shape. The 3-Finger Adaptive Gripper is ideal for advanced manufacturing and robotic research. It adapts to the object’s shape for a solid grip, so you can focus on the task and not the grasping.

- Best option for maximum versatility & flexibility. It picks up any object of any shape.

- 4 grip types: Pinch, Wide, Scissor & Basic

- Control fingers separately; get feedback from each finger

- Install & program your robot in a few minutes with the Gripper URCap

- Rugged and reliable - Fully metallic

- Extremely wide stroke, opens up to 155 mm

Force Torque Sensor

You don’t need a background in robotics to use the FT 300-S Force Torque Sensor. Its intuitive programming interface guides you through the steps to an efficient force-sensitive application.

- IP65 Rating

- Stiff metal composition ensures high accuracy

- Wear-free sensing technology doesn’t require calibration; no production downtime

- Precise, repeatable, and high-resolution measurements

- Constant force and stiffness for each axis

- Precise object placement

- Adjustable tool weight based on center of gravity

- Includes Force Copilot intuitive programming interface

Force Copilot

Force Copilot is an intuitive software to operate the e-Series’ embedded force torque sensor. Program complex robot movements in minutes—no robotics expertise needed. The result is a reliable and flexible robot cell.

- Force control made easy

- Intuitive software to operate the Force Torque Sensor

- Program complex robot movements in minutes; no robotics expertise needed

- Increase robot cell reliability and flexibility

- Uses the Force Torque Sensor data along with Force Copilot features to allow the programming of force-sensitive applications

Finishing Copilot

You don’t need a robotics background to use Finishing Copilot. Its intuitive programming interface guides you through the steps to set up an efficient finishing application.

- Software made for Finishing applications using cobots from Universal Robots

- Save hours of programming

- Generate a finishing path in minutes with fewer than 10 waypoints

- Compensate for external tool wear

- Set an external tool center point

- Validates part position and automatically adapts all related parameters

- Apply constant force and define the stiffness for each axis

- Achieve .2 mm precision

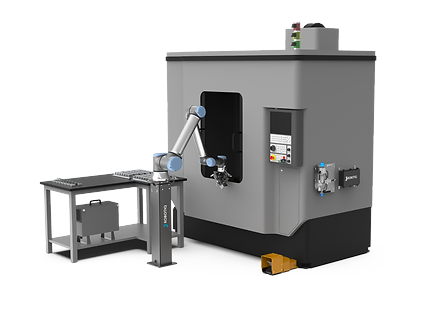

Machine Tending

Start production faster and keep the chips flying with Robotiq’s Machine Tending Solution. With today’s labor shortage, it is extremely difficult to find people to manually load and unload parts and material into a CNC. By automating this process, you can elevate your workforce and let your CNC machines tend themselves.

- Ensures constant production, increasing your production hours and reducing downtime.

- Deploys in hours on any CNC.

- Powerful software guides you through setup from start to finish, making a complex application simple.

- Non-invasive CNC automation that will monitor machine systems, start machine cycle, and control workholding.

- Delivers an ROI of 6 – 12 months.

Palletizing

Take advantage of a turnkey solution designed to provide immediate functionality and operational efficiency. Robotiq’s AX and PE Series Palletizers are adaptable to manage a wide range of box sizes, shapes, weights, and package materials. Their compact size fits easily within your floor space and integrates seamlessly on existing systems.

An intuitive interface and intelligent software make it easy for anyone to operate, regardless of robotics knowledge. The software consistently optimizes trajectories to maximize cycle time for a solution that offers the greatest speed and highest payload capacity.

Sanding Kit

Automate one of the toughest, dirtiest jobs in your shop by adding Robotiq’s Sanding Kit to a cobot. This complete solution eases hardware and software component communication, simplifying integration and getting your production started faster.

- Program sanding applications the easy way, no robotics expertise required

- Reduce programming time from hours to minutes

- Improve quality and consistency

- Increase productivity

- Reduce worker injuries related to ergonomics issues

- Supported materials: carbon fiber, fiberglass, metal, plastic, solid surface, wood

Solutions

Robotiq Collaborative Robot eBook

The new Collaborative Robot ebook provides a comprehensive review of 9 emerging collaborative robots for industrial applications. This ebook includes a comparative chart for all the main specifications for each robot.

Download your ebook

Production Monitoring

Insights Software from Robotiq

How often do machines sit idle before anyone notices that they’re offline due to an issue? With Insights from Robotiq, you can be sure that this doesn’t happen with your collaborative robot from Universal Robots. Remote monitoring and alerts enable you to get the robot back online and back to production faster.

- Minimize Downtime – get real-time alerts, remote access lets you restart production faster.

- Monitor Production – define and track KPIs to see trends in production.

- Optimize Production – track progress, analyze trends, and improve efficiencies to maximize your ROI.

- For use with Universal Robots UR3e, UR5e or UR10e (with CB3.1 controller) cobots