Parker Tough Shield Plus

Parker ToughShield™ Plus

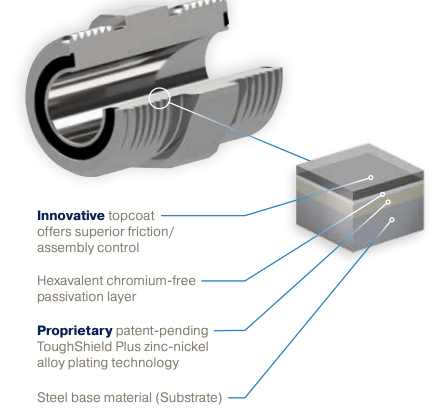

Parker’s innovative ToughShield™ Plus plating technology

The new standard zinc-nickel (Zn-Ni) plating for Parker steel tube fittings and adapters worldwide offers premium corrosion resistance, protecting your equipment significantly longer than other commercially available plating technologies.

Parker engineers and metal scientists used state-of-the art tools and analysis methods to study corrosion and how to minimize it. This led to the development of our patent-pending advanced plating which provides superior corrosion and assembly performance, even on products subjected to after plating deformation such as swivel nuts and other fluid power components.

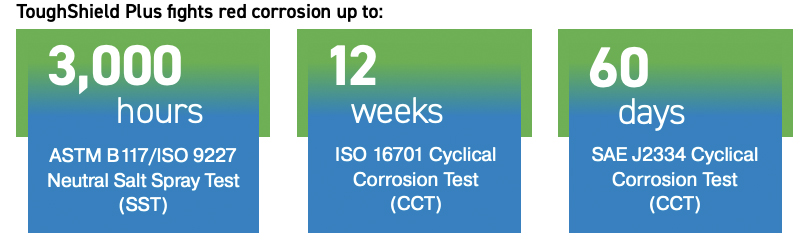

Premium performance validation

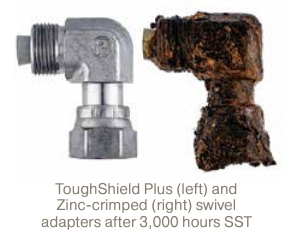

The superior corrosion resistance of Parker's latest plating technology is validated through ASTM B117 / ISO 9227 neutral Salt Spray Testing (SST), as well as two Cyclical Corrosion Tests (CCT) - ISO 16701 and SAE J2334. CCT is widely considered to provide a closer correlation to field corrosion conditions. ToughShield Plus is the first standard plating system in the fluid power industry proven to offer this exceptional level of resistance to red rust.

The Parker zinc-nickel difference

Parker ToughShield Plus delivers more than superior corrosion protection. This upgrade is drop-in compatible with no changes to assembly procedures or performance, including when used with zinc plated components.

Corrosion spreads fast

Chemicals, fertilizers, mud, high humidity and temperatures, salts, and air pollution are all factors that cause corrosion. Once it starts, it can quickly spread from fittings/ adapters to other system components. For example, it can migrate to cylinders or hydraulic hoses requiring costly replacement or repair.

Cost of Corrosion

The true cost of corrosion extends beyond the replacement costs of connectors. It includes the associated downtime when equipment and personnel are idle. Even new equipment exposed to corrosive elements during long ocean freight journeys can require expensive OEM warranty claims. This makes it essential to avoid the risk of corrosion from the onset.