Parker

Parker Hannifin is the global leader in motion and control technologies. We're creating innovative products and systems to improve quality of life for all. Our hydraulic technology center in Kentucky, southern Indiana, and southern Illinois offers our customers access to our full range of world-class products, including pneumatic cylinders, liquid and hydraulic systems, pneumatic systems.

Products

Hoses

Parker offers the largest selection of hoses plus more fitting sizes than any other manufacturer. You'll find a wide variety of hoses including braided, spiral and multi-purpose, and more than 4,500 Parkrimp fittings. Parker products have been designed, tested and approved to meet and exceed global standards. The right product is available for your application, including hose that features a variety of abrasion resistant cover choices, flexibility, a wide range of media compatibility and more - characteristics that make Parker the hose supplier of choice for customers that demand the most from their equipment.

Composite Hose

Composite Hose from Parker Offers Lasting Value for Petrochemical Applications Parker composite hose is a unique alternative to traditional rubber and metal hose. It provides lighter weight, superior flexibility, minimal force to bend and unparalleled kink and vibration resistance, making it suitable for a wide array of petrochemical fluids in loading/unloading, Composite hose processing, transfer and transport applications. Parker composite hose assembly systems-using a new generation of hose constructions, innovative dry seal coupling technology and Parker crimping equipment.

- Save time and expense

- Quick fabrication

- Easy installation

- Superior long-lasting performance

Compact Spiral Hydraulic Hose

This innovative flexible compact spiral hydraulic hose provides a notably long service life, meeting twice the number of required test cycles for use in both stationary and mobile industrial machinery in a wide range of applications, including General Industry Manufacturing, Construction, Defense, Compact Spiral Hose Oil and Gas. This new compact hose product offers high-end hose performance at 5,000 or 6,000 psi.

- Smaller outside diameter and tighter bend radius

- Improved productivity because your hose is easier to route and install which saves valuable labor time and effort

- The option to use larger size hose for better flow characteristics in tight space applications

- This new hose weighs up to 26% less than standard spiral hose reducing shipping and packaging costs.

Parker GlobalCore Hose

Together, we can reduce your inventory with a cohesive family of hoses and fittings.

You know Parker as the global leader in providing unprecedented performance and value for hydraulic systems with high-pressure applications. With their GlobalCore solution, you can simplify your part number complexity

with a globally available, cohesive product line of high-performance constant working pressure hoses. Providing a simple solutions of robust hydraulic hoses designed to endure the tough conditions where work gets done,

GlobalCore is the future that OEMs and end users around the world have been asking for.

Designed, built, and tested to the ISO 18752 specification, GlobalCore reduces engineering and service complexity by providing the first comprehensive product family across the most commonly used constant working

pressure classes.

DOWNLOAD GLOBALCORE BROCHURE

Solutions

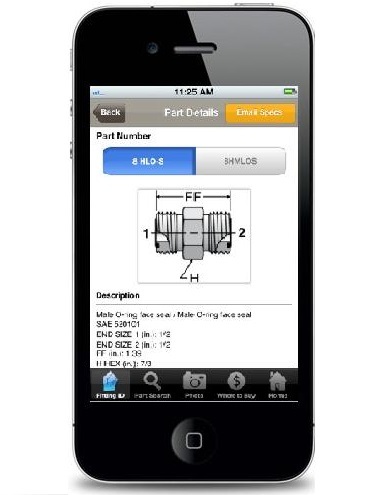

Parker Fitting Finder APP

Parker fitting identification and locator for finding the correct part number of many of the Parker fittings you seek. A handy distributor locator and CAD models are also included.

HoseFinderAPP

Parker Hose Selection Guide Search thousands of products in categories such as hoses, fittings, crimpers, accessories and more, or use Parker's STAMP process to search for an appropriate hose for your application.

- S = Size

- T = Temperature

- A = Application

- M = Media

- P = Pressure

Parker Tracking System

Global Asset Tagging and Identification System

PTS labels are specifically engineered to withstand harsh chemicals, temperatures, UV exposure and other challenging conditions. Call with the serial number of a damaged hose, and it will be ready for you when you come

in, no waiting or bringing in your old hose. Download brochure

Find a Parker Store location near you

Connectors

Parker's Quick Coupling Division has been supplying quality products to the marketplace since it's inception. With five manufacturing facilities on two continents, Parker QCD manufactures hydraulic and pneumatic products designed to meet the demanding requirements of a wide variety of applications in a host of markets including Agriculture, Automotive, Chemical, Off-Shore Oil, Pulp and Paper, Printing and Publishing, Plastics, Public Utilities, Construction, Alternative Fuels and others.

Pneumatic Automation Connectors

Compact, lightweight, composite fittings commonly used in pneumatic automation applications. The most economical push-to-connect choices as well as integrated fittings, flow control and check valves. Nylon and Polyurethane tubing available in multiple transparent and opaque colors for system color-coding.

Parker Water & Beverage Fittings

Parker push-to-connect and barb full flow profile fittings for water applications are suitable for water, potable liquids, and neutral gas applications. They offer high chemical resistance to such things as chlorine, cleaning agents, and UV.Made of an engineered polymer for superior mechanical strength and chemical resistance, Parker ball valves offer an innovative design for maximum capability and optimum performance. Parflex Series EA antimicrobial PE tubing is specially formulated with Sanitized? to resist degradation from mildew, algeae, fungi and biofilm that can accumulate on the inside and outside of tubing in filling and processing applications.

DOT Transportation

Robust all-brass or light-weight, composite push-to-connect fittings meet SAE J2494 and D.O.T. specifications. Designed for all D.O.T. truck and trailer applications, Parker PTC fittings reduce assembly time versus compression style fittings by 90%. Parker's transportation connection solutions include:Parker Transportation Connectors

- Encapsulated cartridges

- NTA fittings

- Air Brake fittings

- Transmission fittings

- Drain cocks

- Truck valves

- Lanyard valves

- Airbrake Nylon Tubing

Industrial

Parker Compact, pre-assembled compression fittings are designed for fast assembly. Flared and inverted flare fittings for a metal-to-metal seal. Pipe fittings meet all functional SAE J512 industry requirements. These High-duty fittings are ideal for oil, coolant or lubrication systems. Ball valves are available in brass, stainless steel and carbon steel in sizes from 1/8" to 3".

Prestolok PLM

Parker PLM fittings with a high phosphorus nickel coating conform to FDA standards.Excellent resistance to high pressure, temperature and aggressive washdown fluids make PLM fittings an ideal solution in applications involving direct contact with food products. The push-to-connect ends reduce assembly time by as much as 30 seconds per assembly when compared to standard Prestolok PLM compression type fittings.

- Excellent resistance to high pressure and vacuum

- Materials conform to FDA standards

- Polymer components meet UL 94 V-0 flammability requirements

- Spring collet gripping for long term resistance

- Can be used in the food industry

- All PLM fittings are Silicone free

Prestolok PLS

Fittings that come in contact with food must be corrosion resistant, non-toxic, non-absorbent and capable of being washed and disinfected. The hygienic design of the Parker PLS fittings reduce the retention zones for safe and easy cleaning. In order to guarantee quality, traceability and performance, Parker PLS fittings offer 100% unit control and dating of the manufactured components.Prestolok PLS

- 316L stainless steel body

- 303L stainless steel collet

- FKM o-ring resistant to the majority of aggressive chemicals

- Smooth polished surface

- Materials conform to FDA standards

- All PLS fittings are Silicone free

Vibra-Lok Connectors

Excellent resistance to vibration, mechanical, shock and tube movement. Vibra-Lok provides a positive reliable seal under vibration conditions, mechanical shock or tube movement. Special Vibra-Lok sleeves resist deterioration and retain flexibility over a wide temperature range. Use with all seamed or seamless metal tubing; Copper, Aluminum, Steel (Bundy), Stainless Steel and Glass. Sleeves are compatible forgasoline, oil, diesel fuel, lubricants, vacuum, air and water service.

FET Series High Pressure Non Spill Quick Couplings

Parker's FET Series couplings are built to be used in high pressure, high impulse applications that require the security of a threaded connection and the ability to connect and disconnect under residual pressure.

- Up to 6000 psi operating pressure

- Connect under residual pressure up to 5000 psi

- Disconnect under residual pressure up to 2500 psi

- Interchanges with similar thread-to-connect couplings

- High impulse resistance, high strength materials

- Robust threaded connection, visual connection indicator

Solutions

SensoNODE Wireless Monitoring Sensors

Parker's SensoNODE Low Energy Wireless Monitoring Sensors and SensoNODE mobile iOS application are the first in a family of products for monitoring pressure, temperature, and humidity in liquid and gas applications. The SensoNODE family puts data in the palms of users' hands, helping to predict problems and prevent downtime in a variety of equipment and facility applications, thus saving time and money on costly labor or repairs.

Developed with the mobile worker in mind, Parker's wireless sensors eliminate the constraints of traditional wired sensors in everyday applications. Small in size and easily installed, the wireless sensors offer a sealed sensor housing to facilitate sensor location in challenging environments where a wired sensor platform is impractical or impossible. There are three individual sensor options that can monitor pressure, temperature, and humidity and transmit live readings to a nearby iOS device. This allows the user to track system performance to predict problems and prevent costly downtime. The sensors are compatible with a wide range of liquid and gas applications. They are optimized for low power consumption and run on a standard coin cell battery. The iOS app is available as a free download from the App Store.

Pumps

Parker's broad line of energy efficient hydraulic pumps includes fixed or variable displacement models of piston, vane and gear pumps. Designed to handle a wide range of applications, Parker pumps are available with a full complement of electronic and computer controls.

Parker P1/PD Medium Pressure Open Circuit Piston Pumps

Parker push-to-connect and barb full flow profile fittings for water applications are suitable for water, potable liquids, and neutral gas applications.

Filtration

Parker filtration products are designed to maximize the reliability of your hydraulic systems and components with positive protection against fluid contaminants. Their comprehensive line of pressure and return line filters enhances machine life, reduces maintenance and lowers costs.High, medium and low pressure filters are offered, as well as portable filter carts and replacement units.

Cartridge Valves

Parker Hydraulic Cartridge

The Parker hydraulic cartridge system offers solutions for almost any circuit. From a simple single cartridge or a complex multi-station assembly, these integrated designs focus on flexibility and innovation. Integrated Hydraulic Circuits advantage

- Reduce the number of fittings, hoses and couplings

- Optimize and reduce components used

- Allow fewer leakage points

- Consume less space

- Provide simplified assembly and service

- Create a complete system solution with optimized functions

- Allow you to flange one or more directional valves as well as pumps, cylinders, motors and filters

360° Rotary Manifolds

Parker Rotary Manifolds are used in applications where multiple rotations of a mechanical structure are required. A hydraulic rotary manifold's primary function is to allow oil, water, gases and electronics to pass through it while allowing a 360 degree continuous rotation. Depending on the application, these manifolds are manufactured in various configurations and sizes containing up to 20 stations and can operate at pressures as high as 7,500 psi. Parker's Rotary Manifolds are designed to provide leak-free performance in the most rigorous applications. Parker's unique step shaft design, proprietary seal design and non-welded barrel ensure the user of extensive service life while providing a compact and easy to fit solution. Download brochure

Control Valves

Parker makes hydraulic valves for virtually every industrial equipment application, from simple on/off functions to precise motion control.

These include control and bankable control valves, motion controllers, servo valves and manifold mounted directional and proportional valves.

Air Hydro Power is a Parker Hydraulic Control Valve distributor in Kentucky, Alabama, and Mississippi. We offer free product evaluations and technical support to help our customers solve their applications.

Motors

Parker's full line of high and low speed motors provide power ranging up to 15,000 inch-pounds of torque with speeds ranging from ½ rpm to 13,000 rpm.

A complete range of sizes is offered in gear gerotor, vane and piston style operating configurations. Fixed and variable displacement motors are available. Parker hydraulic motors deliver excellent performance with high efficiency, true wear compensation and longer service life.

Cylinders

Parker Hannifin's Industrial Cylinder Division offers products that are designed to meet and exceed the most demanding application requirements. Our extensive product line offers OEM's and End Users hydraulic cylinder solutions that provide value through reduced maintenance, increased productivity, and long service life.

Parker Industrial Cylinder's wide breadth of product encompasses NFPA, ISO, and Custom designed products in a multitude of configurations and sizes.

Power Units

Compact, powerful and efficient performance is delivered fromParker Oildyne products. Robust, simple designs provide power density, easy installation and flexibility for use across a wide variety of applications.

Reliable solutions for your design challenges include electro-hydraulic actuators, miniature power units, fluid power systems, piston pumps, cartridge piston pumps and hand pumps. High quality and smooth, quiet operation make these products a durable fit in the design arena. Locking circuits and manual release availability enable safe, secure operation in critical situations and harsh environments. Extended services life dramatically lowers maintenance requirements and costs.

New Drive Controlled Power Units - DCP

Drive Controlled Pump (DCP) option for H-Pak power units couples an AC10 drive from Parker's SSD division with an H-Pak power unit, providing a simple solution for variable speed energy savings. Delivered completely assembled and factory tested, the DCP H-Pak comes with five different preconfigured options.

The DCP H-Pak addresses issues of inefficient energy use and helps in meeting increasingly strict environmental regulations. Durable and efficient, DCP power units perform well in applications with long dwell times. They are ideal for a diverse range of applications.

Other benefits include an up to 40 percent reduction in hydraulic operating temperatures, quieter operation, increased component life spans and an economical, compact footprint. For more information visit www.parker.com.

Tubing

Whether you need airbrake tubing, medical tubing or a particular material, such as PVDF or metric metal tubing, Parker makes it. Parker delivers one of the largest selections of tubing available from one manufacturer. Sizes range from .015” I.D. up to 6” O.D. depending on style.

83FR Duragard

Whether your business features automotive robotics, power tools or shop air lines, Parflex 83FR with DuraGard Flame Resisitant Hose should be considered the hose of choice for demanding applications. This tough, flame-resistant hose combines superior design with quality materials to deliver reliable, lasting performance. 83FR DuraGard is a non-conductive, weld spatter resistant polyurethane hose, often used in robotic assembly applications. Although lightweight, the hose features a strong, bonded construction, providing excellent kink resistance while minimizing hose fatigue. The economical 83FR offers easy assembly with Parker's vast selection of Push-Lok and crimp fittings and is available in a variety of cover colors and long lengths.

Ulratlite Superbraid

Ultralite Superbraid polyurethane air hose is 29% lighter than equivalent thermoplastic air hoses and 63% lighter than rubber. Ultra-Lite Superbraid utilizes a strain relief and has standard sizes range from 1/4" to 3/4" I.D. Extreme flexibility and ability to lay out flat without kinking or looping make it the most user friendly hose available. Ultralite Superbraid features rugged fittings made from corrosion resistant brass that will withstand the roughest treatment. This state-of-the-art strain relief protects the hose at the weakest point (at the barb) while enhancing the appearance of the entire assembly.

Parker Industrial Jackhammer Hose Assemblies

These high-quality 3/4" x 50' hose assemblies are "Made in U.S.A." with a 4:1 design fact and up to 300 psi working pressure. Jackhammer hose Designed for the most rugged applications. These are made of abrasion-resistant EPDM rubber tube and cover to provide years of great service and backed by Parker, a name you can trust.Download PDF here

Parker Twinhammer™ Bonded Air/Water Jackhammer Hose Assemblies

Parker Series 7084 Twinhammer™ Hose is the FIRST factory-assembled dual hose system! This hose is designed with dual air and water lines to be an ideal solution for silica dust suppression in pneumatic jackhammer applications. This hose is user-friendly and easy to install. The blue and red hoses make it easy for users to identify the hose for air service (red) from the hose for water spray (blue).

- Transfers air to power heavy duty pneumatic jackhammers/breakers

- Transfers water to suppress silica dust produced by tool operation

- Features durable, abrasion-resistant lines

- Eliminates the need for clamps, straps, or zip ties

- Quick disconnects for air systems and rust resistant brass couplings for the water supply

These hoses can help customers with safety standard compliance designated by OSHA

Parker E-Z Form™ Hose

Parker E-Z Form hose is designed for installations where tight bends exceed the bend radius of other hoses. Eliminates design, fabrication time and/or required tooling.

Two versions

Multi-purpose (MP) products feature an oil resistant nitrile inner tube, reinforcing plies with a helical wire, and a neoprene cover.

- Temperature range:-20°F to + 180°F

- 75 PSI Max. working pressure

- Full vacuum rating

General Service (GS) products feature an EPDM inner tube and cover with reinforcing plies with a helical wire.

- Temperature range:-40°F to +257°F

- 75 PSI Max. working pressure

- Full vacuum rating

E-Z Form Hose

Crimpers

Parker's Parkrimp family of crimping machines enable any user to make factory-quality hose assemblies quickly, easily and cost-effectively.

The Parkrimp-style crimpers are designed to crimp fittings to the proper diameter every time. These crimpers are simple to operate and they're built to provide years of dependable service. Designed to produce accurate crimps from the first time it's used, Parkrimp crimpers require no calibration and continuously produce proper crimps, time after time.

Mechanical Crimp Connection

Mechanical Crimp Connection for piping or tube systems saves the time and costs of welding For today's piping or tube assemblies, Parker's Mechanical Crimp Connection (MCC) eliminates time-consuming, costly welding - and ensures reliable, leak-free performance. MCC consists of a simple hydraulic assembly tool, specially designed bite ring and adapters. The bite ring attaches to the pipe or tube and secures the adapter. Internal seals in the MCC adapter ensure a leak-free connection and protect against ingression mechanical crimping of adapters to tube or piping.

- Eliminates time and costs of welding and post-weld processes

- Quicker, easier assembly promotes increased equipment uptime

- Inherently safe, clean process

- Internal sealing components ensure leak-free performance

- 6000 psi/415 bar pressure rating at 4:1 design factor

Horizontal Crimper

TH8-450 Production Crimper for fast and accurate crimping. With Parker's horizontal crimper, anyone can make factory quality assemblies quickly, easily and cost effectively. An MCC assembly can be crimped within five minutes! It provides lighter weight, superior flexibility, minimal force to bend and unparalleled kink and vibration resistance, making it suitable for a wide array of petrochemical fluids in loading/unloading, Composite hose processing, transfer and transport applications. Parker composite hose assembly systems-using a new generation of hose constructions, innovative dry seal coupling technology and Parker crimping equipment.

- Save time and expense

- Quick fabrication

- Easy installation

- Superior long-lasting performance

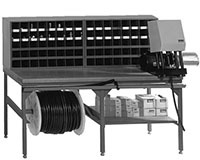

Workstations

Parker's hose assembly work stations is an optimal way to organize and increase productivity while manufacturing hose assemblies.

These Workstations are ideal for plant hose assembly production sites and over-the-counter business locations.

Parker Portable Kart

The Parker Kart organizes and stores all your necessary Parker hoses, fittings, power and hand tools - everything you need to make fast hose assemblies on site.As a valued addition to any facility, Parker Kart will save on downtime and labor costs, as well as eliminate errors in cutting and fitting attachment.With Parker Kart, you'll always have the materials you need, right when and where you need them.

HoseFab Table

The HoseFab Table provides the perfect workstatin for hose fabrication.This heavy duty constructed table provides for mounting Minikrimp, Karrykrimp, Karrykrimp 2, or Parkrimp 1.HoseFab Table is available in 3 versions to meet your requirements with options including two 40B-Cabinets or 72B-Cabinets for fitting storage.

Rotary Reel Racks

Parker Safety Step offers several mobile hose reel rack configurations providing convenient access to hose reel stock.These upright racks are compact and rugged in design.

- 3 Reel Rack (optional 4th reel)

- 16 Reel Capacity

Fitting Stock Bins

The Safety Step fitting stock bins helps Keep your fittings and tubing accessories organized. Available with 40 or 72 openings the stocking bin features 4 ½" openings and heavy duty construction. Parker Safety Step home page