Nason

When it comes to your designs, there’s no reason to compromise. You can count on Nason for everything you’d expect from a premier pneumatic automation company, from accurate, reliable switches to compact, space-efficient cylinders and precise, state-of-the art transducers. If we don’t have exactly what you need, let us know. We’ll build it for you right here in our South Carolina facility.

Products

Cylinders

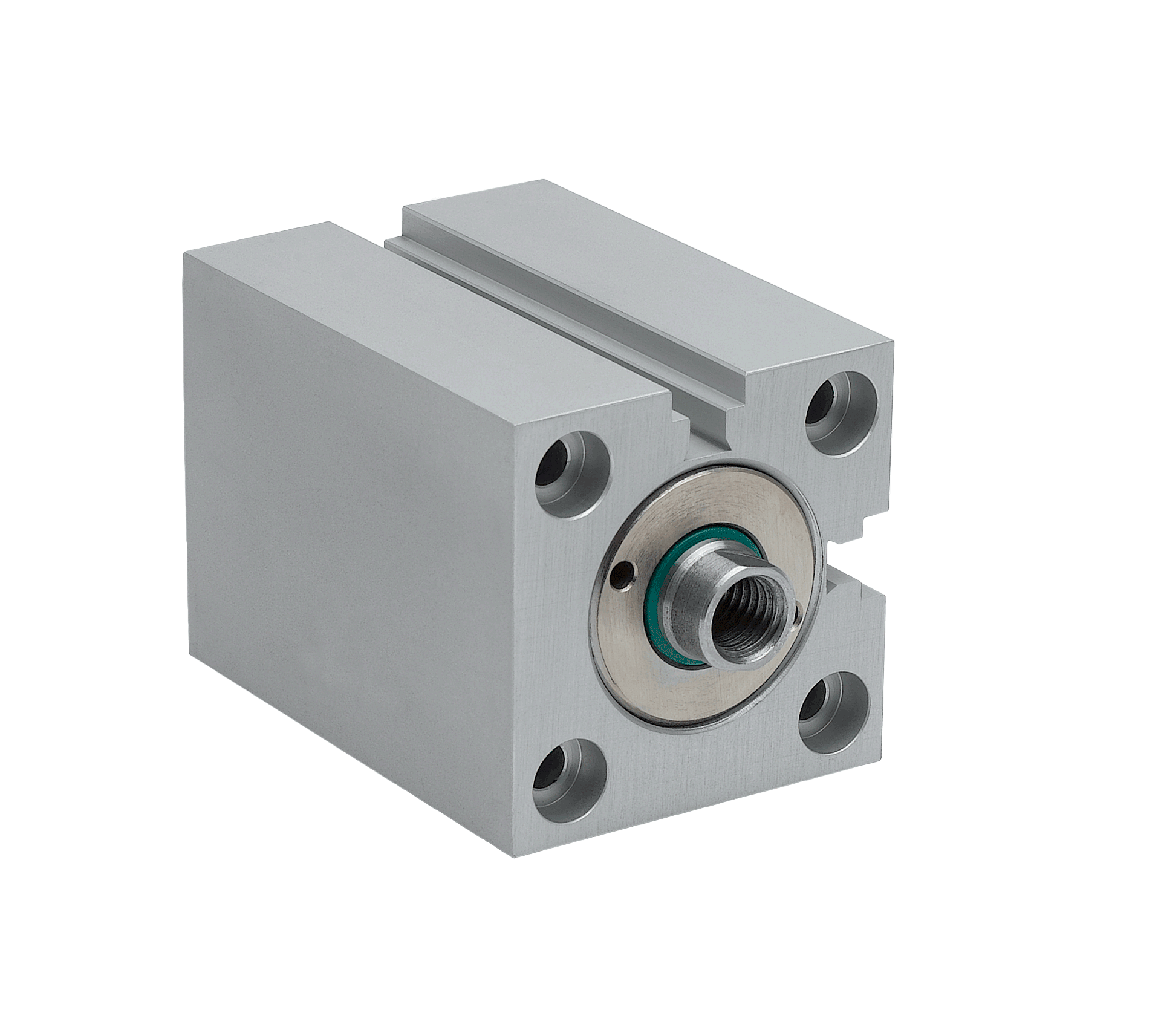

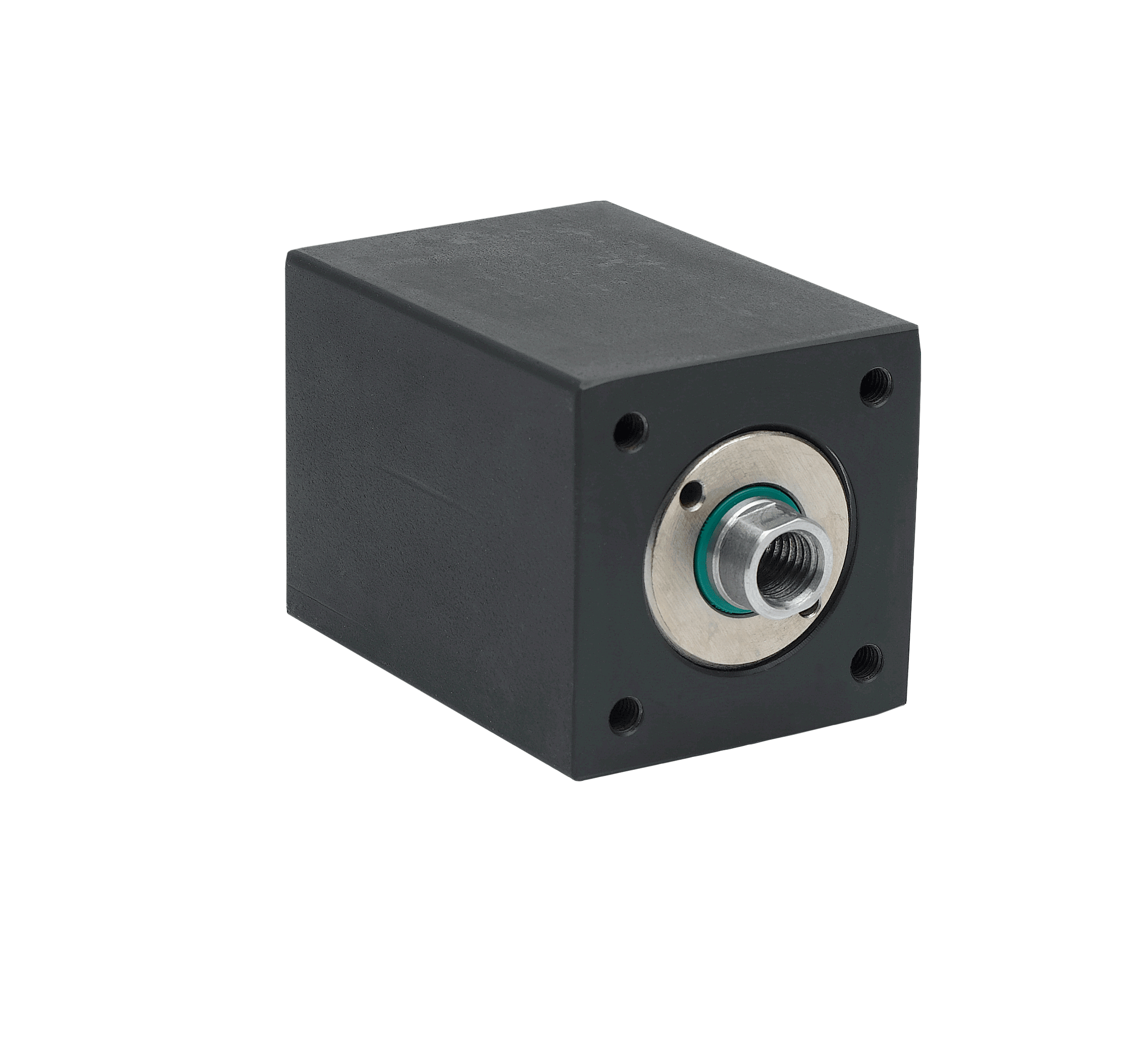

When it comes to cylinders, efficiency matters. Even though our compact linear actuators take up less space than competitors’ products, they deliver the same power as larger competitive products. This allows you to downsize without compromising power capacity.

Nason’s custom-drilled cylinders are precision-manufactured in the USA from durable aluminum or stainless steel, for greater flexibility, better performance, and longer seal & cylinder life.

1. Hydraulic Cylinders

Nason’s compact, heavy-duty hydraulic cylinders transfer force through uncompressible hydraulic fluid to move pistons in a desired direction.

L Series

Available in three models (LS, LE and LH), Nason’s L Series Low Pressure Hydraulic Cylinders (20mm - 76mm bore, 500PSI) were designed with today’s automation equipment in mind.

L15 Series

Nason’s L15 Series 1500 PSI Hydraulic Cylinders were designed to offer compact, long-lasting performance for low-friction applications.

L20 Series

Nason’s L20 series 2000 PSI compact hydraulic cylinder is offered in single- and double-rod configurations with inch or metric mounting and porting. Its aluminum body allows easy integration of traditional PNP or NPN solid-state sensors at end-of-stroke positions, which eliminates the need to invest in costly linear transducers or proximity sensors and provides a more economical, flexible sensing solution. The L20 delivers durable, long-lasting performance for demanding applications.

L30 Series

Nason’s L30 series 3000 PSI compact hydraulic cylinder is offered in single- and double-rod configurations with inch or metric mounting and porting. This low-profile cylinder delivers durable, long-lasting performance for today’s most demanding applications.

2. Pneumatic Air Cylinders

Nason’s pneumatic cylinders are compact air cylinders that convert the potential energy of compressed gas to linear mechanical energy.

Proportional Control Systems

The high output of a pneumatic cylinder with the programmability of an electric actuator.

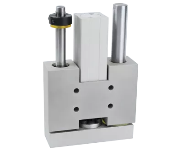

H-Block Series

Ideal for automated systems, manufacturing operations, and other demanding load-bearing applications, these rugged linear actuators accept linear ball bearings with case hardened steel guide rods to provide high load capacity, low deflection, and low friction.

L Series Pneumatic

Available in three models (LS, LE and LH), Nason’s L Series pneumatic cylinders were designed with today’s automation equipment in mind.

CR Series Stainless

Designed for smooth startup and operation, the CR Series’ precision-machined stainless steel components and low-friction bearings ensure long life and effortless operation.

SC Series

Available in seven different mounting styles and three rod end configurations, Nason’s compact SC Series stopper cylinders were designed for today’s demanding conveyor systems — with more power in a smaller footprint than comparable models on the market.

LC Series

Available in both side- and rear-mounted variations, Nason’s LC Series guided pneumatic cylinders were designed for today’s demanding design requirements. These compact, load-carrying pneumatic cylinders are non-rotating and deliver long-lasting performance.

NFPA Series

Nason’s NFPA Series 250 PSI pneumatic cylinders feature precision-machined bores and floating rod bearings, delivering the highest-quality engineering available.

ISO 15552

Built to the globally recognized ISO 15552 standard, Nason’s new ISO cylinders deliver the versatility and rock-solid reliability engineers count on, without compromising lead time or customization. Specify rod extensions and rod threads, and we’ll ship limited-quantity orders in as little as 3–5 business days from our South Carolina facility.

Drop-in interchangeability with other ISO 15552 cylinders simplifies design updates and retrofits.

Bore sizes from 32 mm to 125 mm and strokes up to 900mm cover applications from compact assemblies to heavy-duty industrial automation. Aluminum heads and 303 chrome plated stainless steel rods help ensure consistent, repeatable force output, cycle after cycle. Units are finished, tested, and shipped from our U.S. plant in days, not weeks, to keep your project on schedule. Select seals, mounts, sensors, and ports without adding to lead time.

3. Accessories

From custom engraving and limit sensors to alignment couplers and shock pads, Nason has the cylinder accessories needed for your specific application.

4. Custom Cylinders

Whether you’re after a standard model or a fully bespoke build, we offer the design flexibility to hit your exact specifications.

Choose from a wide catalog of bore diameters, stroke lengths, mounting styles, and port positions, or we can rapidly assemble a tailored combination using modular, pre-engineered components.

Switches

Unlike competitors’ switches, that “creep” between on and off, Nason pressure switches, pneumatic switches, and temperature switches are built for reliable positioning. Made in the USA, these compact and customizable switches feature a snap-action device, which makes their design more precise and repeatable. Their elastomer diaphragms or pistons move a precise .040 of an inch to ensure accurate, instantaneous contact under all operating conditions. Our pneumatic, temperature and pressure switches are UL, CSA, and military approved with an operational life of over one million cycles and a large variety of electrical connections. Need a switch with specs you don’t see? Just ask us. We’ll be happy to custom build it for you.

1. Pressure Switches

Nason pressure switches offer accurate, long-life switching and easy integration in industrial automation, with applications ranging from backup horns on forklifts to braking and steering controls in military vehicles to everyday manufacturing lines. Choose a diaphragm switch for low to medium pressures or a piston switch for higher ranges to get crisp on/off performance and consistent set points. Every unit is configurable with broad media and electrical connection options.

SM

Designed to meet NEMA 4 & 13 standards, the SM fixed low-pressure switch is factory-set and handles a maximum operating pressure up to 250 PSI. Set points span 2–120 PSI, and base materials include brass, aluminum, nickel-plated, steel, 303 SS, and 316 SS.

LM

The tamper-resistant LM fixed low-pressure switch meets NEMA 4 & 13 standards and is factory-set, withstanding a maximum operating pressure up to 2000 PSI. It features set points from 10–300 PSI and is available in base materials such as brass, nickel-plated, steel, 303 SS, and 316 SS.

CF

The factory-set CF high-pressure switch covers set point ranges from 10–7500 PSI. Hardened steel pistons support long life in extreme conditions, while a durable elastomer diaphragm coupled to a piston sensor helps maintain precision without creeping. Base material choices include brass, nickel-plated, 303 SS, and 316 SS.

CJ

Compact and field-adjustable, the CJ adjustable low-pressure switch is designed to meet NEMA 4 & 13 standards and comes in base materials including brass, aluminum, nickel-plated, delrin, 303 SS, and 316 SS. A long-life elastomer diaphragm prevents creeping, and five ranges spanning 3–1500 PSI enable fine-tuned adjustments.

CD

The CD adjustable high-pressure switch offers eight adjustment ranges from 10–7500 PSI and can be configured for enhanced environmental safety. A long-life elastomer diaphragm minimizes creeping, and settings can be dialed in for consistent, precise adjustability. Available base materials include brass, nickel-plated, 303 SS, and 316 SS.

2. Temperature Switches

Used in a wide variety of manufacturing and industrial processes, Nason’s temperature switches act as a limit sensor, opening or closing a circuit when temperature rises above or falls below a defined setpoint. Nason’s temperature sensor switches feature a “no-creep” design with a snap-action electrical device activated by an elastomer diaphragm or piston. These temperature switches keep their contacts in either an open or closed state. When sensors indicate that a precise pre-determined temperature has been reached, they snap over center to a new state. They will remain in this state until the thermal readings rise or fall back over the set point, triggering the temperature switches to snap back to their original state.Our temperature switches offer a wide variety of electrical connection options, are fully customizable and have an operational life of over one million cycles under most operating conditions.

TF

Affordable and compact, the TF is designed for lower temperature applications up to 100,000 cycles and has hysteresis built-in.

TW

The factory-set TW temperature switch features set points from 140-300ºF (60-148ºC). These hydraulic temperature sensors offer a wide differential utilizing a snap action device.

TT

The factory-set TT temperature switch features set points from 40-300ºF (4-148ºC). These hydraulic temperature sensors offer the industry’s largest range of media connections and probe lengths.

3.Vacuum Switches

With factory preset or field adjustable versions, vacuum models range from 1" to 29"Hg. These switches are 100% tested for accuracy and are available as NEMA 4 and 13.

JV

The compact, field-adjustable JV adjustable vacuum switch is built to last and customizable to fit your specific applications. A variety of base material options are available, including brass, aluminum, nickel-plated, delrin, 303 SS, 316 SS, and CF.

VM

The VM vacuum switch offers a space-efficient, cost-effective solution, designed to handle positive pressure and factory-set for tamper resistance out of the box.

VF

The VF fixed vacuum switch offers a space-efficient, cost-effective solution and is factory-set for tamper resistance.

Transducer

Unlike switches, which are either on or off, pressure, vacuum and temperature transducers provide a continuous output range as they convert measurements into various outputs. Nason’s compact transducers range from basic temperature transducers to highly customized wireless pressure transducers. Hydraulic and pneumatic designs with accuracy ranges of 1%, .4% & .25% and .15% and vacuum ranges up to 10,000 PSI serve a variety of industrial applications. Not sure where to start? Click to find out what applications pressure transducers are best used for.

NTBT-DL

The industry-first Bluetooth® certified wireless pressure transducer with long battery life and patent- pending design makes the NTBT-DL a perfect fit for many applications for Industrial and Home Automation.

NTS

The low-cost NTS temperature transducer provides highly accurate temperature readings across a wide range of applications. Using industry-standard analog outputs and built with 316 stainless steel wetted parts, the NTS is accurate to within 1%.

The low-cost NTS temperature transducer provides highly accurate temperature readings across a wide range of applications. Using industry-standard analog outputs and built with 316 stainless steel wetted parts, the NTS is accurate to within 1%.

NT

Made in the USA, the budget-friendly NT Series pressure and vacuum transducer packs powerful piezoresistive ceramic pressure sensors into a compact, low-cost body available in all-brass or 316 stainless steel. Reliable and easy to install, the NT delivers 1% accuracy and sets a clear price-to-performance standard for high-volume commercial and industrial applications. It is highly customizable with a large offering of media and electrical connections to match your requirements.

NTS

The low-cost NTS temperature transducer provides highly accurate temperature readings across a wide range of applications. Using industry-standard analog outputs and built with 316 stainless steel wetted parts, the NTS is accurate to within 1%.

The low-cost NTS temperature transducer provides highly accurate temperature readings across a wide range of applications. Using industry-standard analog outputs and built with 316 stainless steel wetted parts, the NTS is accurate to within 1%.

NT110

The NT110 series low-cost pressure transducer is compact and easy to install, with vacuum ranges up to 285 PSI or 3–10,000 PSI. It utilizes piezoresistance technology in a 316 stainless steel body with stainless steel diaphragms for durability and media compatibility. A dependable workhorse, this vacuum pressure transducer offers 1% accuracy, low power consumption, and long-term stability, bringing high quality at a modest price for a wide array of applications.

The NT110 series low-cost pressure transducer is compact and easy to install, with vacuum ranges up to 285 PSI or 3–10,000 PSI. It utilizes piezoresistance technology in a 316 stainless steel body with stainless steel diaphragms for durability and media compatibility. A dependable workhorse, this vacuum pressure transducer offers 1% accuracy, low power consumption, and long-term stability, bringing high quality at a modest price for a wide array of applications.

NT41

The NT41 series piezoresistance pressure transducer is easy to install and features vacuum ranges up to 285 PSI or 3–10,000 PSI in an all-stainless body with stainless steel diaphragms. Ideal for high-volume commercial and industrial use, this compact transducer delivers 0.4% accuracy, reliable performance, and long-term stability, while packing strong capabilities into a small footprint at a budget-friendly price.

The NT41 series piezoresistance pressure transducer is easy to install and features vacuum ranges up to 285 PSI or 3–10,000 PSI in an all-stainless body with stainless steel diaphragms. Ideal for high-volume commercial and industrial use, this compact transducer delivers 0.4% accuracy, reliable performance, and long-term stability, while packing strong capabilities into a small footprint at a budget-friendly price.