MIR

Mobile Industrial Robots is the global market leader in collaborative mobile robots, dedicated to developing user-friendly, flexible, and safe robots to help companies increase the efficiency of their operations. With a rapid return on investment, MiR robotic systems are an essential piece of equipment for businesses looking to optimize their logistics operations. MiR's autonomous robots take over monotonous and time-consuming tasks, freeing up employees to focus on more value-adding work.

Products

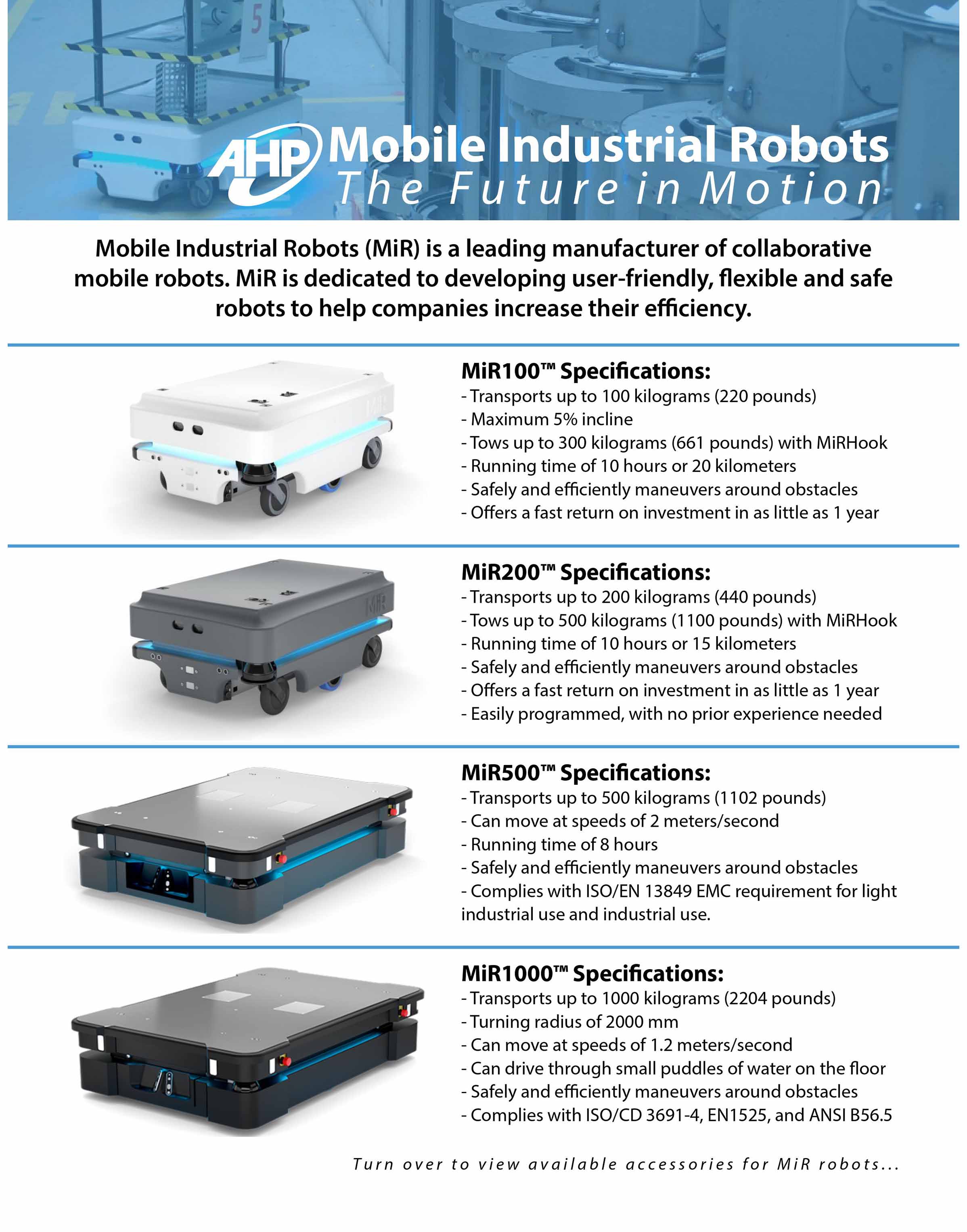

MiR250

MiR250 is a more flexible AMR that can work around the clock and is brilliantly simple to setup, for improved productivity. Its smaller footprint and increased adaptability help optimize internal logistics without changing layout.

The MiR250 has a footprint of 580 x 800 mm and a height of only 30 centimeters while still being able to move as much as 250 kg with a speed of 2 meters/second. This makes the AMR more agile than any other AMRs on the market and highly adaptable for challenging environments. Thanks to the small footprint, it can drive in spaces as narrow as 80 centimeters. So, doors and elevators that can be an obstacle for other mobile robots, are not a problem for the MiR250.

The MiR250 can be charged twice as quickly as our other smaller mobile robots, corresponding to an extra three hours of operation per 24-hour period for a robot that operates round the clock.

MiRHook 250

MiRHook 250 Increase the efficiency of internal transportation tasks with the patented extended-payload MiR250 Hook mobile robot solution that automatically picks up, transports and drops off carts with up to 500kg payload. The MiR250 Hook is a user-friendly and efficient mobile robot solution consisting of the MiR250 AMR and the MiR Hook 250 top module for fully automated pick-up and towing of carts in production, logistics and healthcare environments.

This versatile solution can collect carts at different heights, so there is no need to modify your existing carts or your layout when you are implementing the MiR250 Hook.

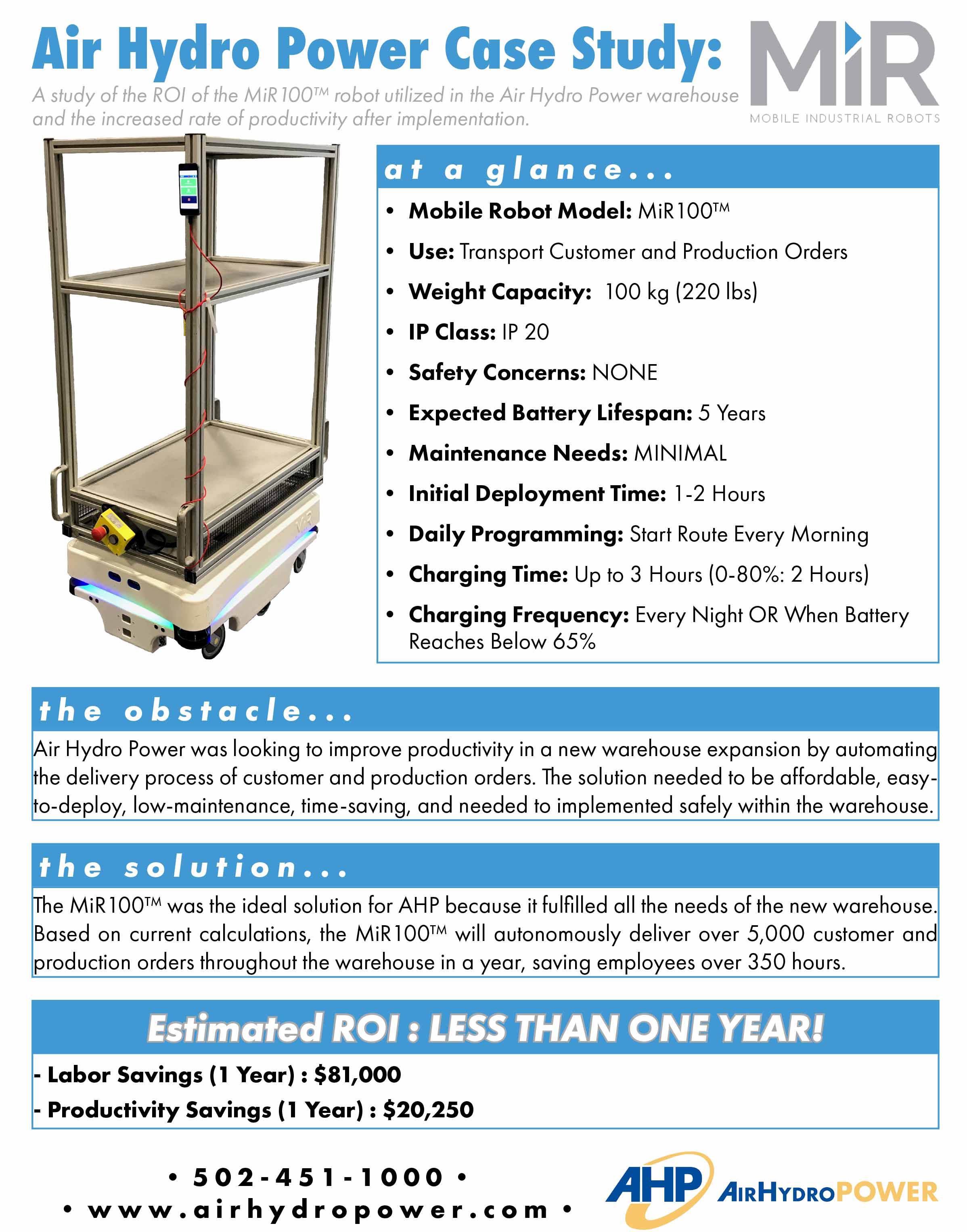

MiR600

The collaborative MiR600 safely maneuvers around people and physical obstacles. With its advanced technology and sophisticated software, the robot autonomously navigates to find the most efficient path to its destination. When it meets obstacles, it will automatically re-route to avoid costly lags in logistics processes.

MiR600 is equipped with the latest laser-scanning technology that delivers a 360-degree visual for optimal safety. 3D cameras have a range of 30-2,000 mm above floor level to detect pallets.

The MiR600 is the first IP52 rated AMR with increased ability to withstand dust particles and fluids the mobile robot can be used in more environments, it can e.g. drive close to open gates or other places where it is exposed to waterdrops and dirt.

MiR1350

The MiR1350 is the most powerful AMR from MiR to date. The MiR1350 is compliant with the highest available robot standards making it superior to other AMRs on the market.

With a payload of 1350 kg (3000 lbs), MiR1350 is the most powerful AMR from MiR to date, and it enables you to maximize the efficiency of your logistics operations. You can efficiently move very heavy loads and pallets automatically with the MiR1350.

MiR1350 is equipped with the newest laser-scanner technology and has optimal safety with 360 degrees vision around itself. Two 3D cameras in the front enables the robot to see from 30 to 2.000 mm. above the floor, and two sensors in each corner contribute to the robot’s ability to see pallets and other obstacles that are so low that they otherwise can be hard for robots to detect.

MiR1200 Pallet Jack

The MiR1200 Pallet Jack revolutionizes internal pallet transportation, automating detection, transport, and delivery of EU pallets up to 1200 kg at 1.5 m/s. Its groundbreaking AI-based perception system sets it apart, reducing pick-and-place cycle times significantly and elevating throughput.

This agile robot operates continuously, with shift-long battery capacity and seamless opportunity charging for uninterrupted performance. Navigating tight spaces effortlessly, it optimizes logistics efficiency, ensuring timely pallet delivery without additional infrastructure.

Perfectly integrating into various value streams, from warehouse operations to core production processes, the MiR1200 complies with the latest safety standards. It safely navigate around people and other obstacles and constitutes a safe alternative to traditional forklifts and pallet trucks. With user-friendly software and quick scaling through MiR Fleet, deploying and managing this solution is straightforward, making it the ultimate blend of precision, performance, and productivity.

- AI-based perception for fast, precise and reliable pallet detection

- High battery-capacity and fast charging for working in 24/7 workflows

- Complies to present safety standards - ISO3691-4

MiR MC250

The MC250 combines MiR’s AMR platform with Universal Robots’ collaborative robot arms.

Seamlessly connected through a flexible, modular platform by Enabled Robotics, this system adapts to various workflows. The cobot arm’s size and mounted grippers can be adjusted for different payloads and tasks. Known for ease of use, the Mobile Cobot, features an intuitive all-in-one interface for efficient programming of both the AMR and cobot arm, enhancing operational efficiency.

- Integrated vision system

- Status light indication system for complete robot

- Integrated safety/E-stop system for complete robot

- Fixing plate with M6 threads for attaching accessories

- Modular and flexible: easy to adapt to your application

Download the MC250 Brochure

MiR MC600

Built on the success of the smaller MC250, the MC600 integrates the MiR600 autonomous mobile robot (AMR) with Universal Robots’ heavy-payload UR20/UR30 cobot to handle heavier items and automate tasks such as palletizing, box handling and machine tending. Capable of handling payloads up to 600 kg (1322 lbs), the MC600 combines the MiR600 mobile robot base with the UR20/UR30 collaborative robot arms from Universal Robots (UR) to automate complex workflows in industrial environments.

Download the MC600 Datasheet

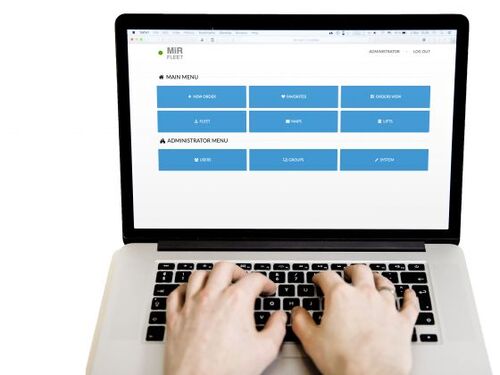

MiRFleet

MiRFleet gives you centralized control of robots throughout your facility from a single, user-friendly, web-based interface.

You can easily program and control a fleet of robots, including managing robots with different top modules, hooks, or other accessories. Once programmed, the system automatically prioritizes and selects the robot best-suited for a job based on position and availability. SMS or email notifications keep you informed of obstacles or other issues that might prevent the robot from completing a task.

MiRCharge

Your MiR robot will never run out of power in the middle of a job. MiRCharge is a fully automatic charging station that offers flexible deployment options to meet your needs.

The robot autonomously returns to the charging station and connects when its battery falls under established limits. It can also be programmed to regularly recharge between deliveries, such as when it returns to a stockroom or depot, which can allow the robot to run nearly continuously. MiRCharge fully charges a MiR robot in about two hours. When multiple robots are deployed using MiRFleet, the system evaluates battery levels and job loads, optimizing utilization and recharging to keep the fleet on the job around the clock.