IAI - Intelligent Actuator

IAI offers complete system solutions, instead of building a robotics system from scratch, design engineers can purchase fully-functional units from IAI and begin production sooner.

Their straightforward programming language and pre-formatted products make it easy to integrate IAI products with other components. Buying off-the-shelf Intelligent Actuator products is more cost-effective than building your own, and puts your project into production sooner With the introduction of a full range of ROBO Cylinders, IAI is also leading the transition away from pneumatics to cost-effective, low-maintenance, and fully-programmable electric cylinders.

Products

EC ELECYLINDER Electric Actuators

Corrugated metal hose can handle high pressures and is gas tight. It is excellent for gas and liquid transfers.

Ushering in a new era of easy electric cylinder control, the easy ELECylinder is designed for simplicity from start-up to maintenance. Speed / Acceleration settings can be set in just 5 minutes. No time-consuming programming is necessary. You can also operate it with ON / OFF signals, like a solenoid valve. No time-consuming programming is necessary.

Air cylinders cannot operate at high velocity due to the impact at stroke end which occurs when excess velocity is applied. The ELECYLINDER can start and stop smoothly at high velocity, reducing cycle time.

- Maintains excellent velocity stability even in the low velocity range

- Acceleration, velocity, and deceleration (AVD) can be set individually

- Teach pendant troubleshooting for easy diagnostics and repair

- Start and end points can be set at any value

- Battery-less absolute encoder means no maintenance required

- Built-in controller requires no control panel space

- Reduces electric bills, the higher the operational frequency, the greater the savings

ROBO Cylinder

Economical and easy to use, the ROBO Cylinder? is specifically designed to accomplish the simple tasks usually assigned to air cylinders, but with greater flexibility and control. Offering custom control over position, speed, acceleration, deceleration, and torque, allowing for mid-move velocity changes, and control from a PLC, the ROBO Cylinder? is a versatile and easy-to-use alternative to pneumatic cylinders.

The ROBO Cylinder? is a flexible, intelligent, and economical, ballscrew linear actuator from Intelligent Actuator offering:

- Multiple Positioning

- 0.02mm Repeatability

- Programmable Velocity Control

- Programmable Acceleration & Deceleration

- Programmable Torque Control (Push Function)

- 50mm to 1000mm Stroke Lengths

- 1mm/s to 1000mm/s Speed (Depends on Model)

- Serial I/O for linking up to 16 axes

- Long life expectancy (5,000km)

- Low Power Consumption (Compared to Air Cylinder Compressors)

IX SCARA Robots

IX SCARA (Selective Compliant Assembly Robot Arm) robots are ideal for high speed, precision operations such as sealing, dispensing, parts insertion, assembly, and more. Best of Class variety of off-the-shelf SCARA robot models (cleanroom, water resistant, wall mount, & more)

- X-SEL? controller for exceptionally easy programming, calibration and troubleshooting

- Absolute encoders (standard)

- Profibus, DeviceNet, CC-Link, & Ethernet Network Communication

- Z-axis "Push" function for easy control of compression force and torque

- Award-winning path control and 3D path capability

- Interference check zones: User-defined outputs turn on when a zone is violated (you can set as many as 10 zones)

- Vision compatible, Ethernet-ready, cleanroom, wall & ceiling mount models available.

Grippers

Motorized Electric Grippers achieve high grip force and long stroke in a compact body. IAI Grippers come in 2 Finger and 3 finger configurations. The slider type with a guide promises excellent rigidity, while the lever type ensures easy gripping of the load because the levers open 180 degrees. Features include multi-positioning and adjustable grip strength.

Linear Actuators

IAI offers a wide range of linear actuator solutions including clean room and high speed high payload versions. The ballscrew-driven linear actuator is based on an extruded aluminum frame with a built-in linear motion guide system.

An AC Servo motor provides closed-loop feedback to the motion controller. Replacing the ball screw with no-friction magnets, the Linear Servo (LS) series magnetic linear actuator delivers exceptional repeatability at ultra-high speeds. And if you are looking to dramatically reduce your cycle time, the LS magnetic linear actuator can accelerate or decelerate at an extremely fast 3G - much faster than even an advanced ball screw linear actuator.

The IF is a belt-driven version of the IS Actuator. By combining the high moment loads of the IS with the speed of the FS, the IF Series has proven itself in providing torsional rigidity, reliability, and high speeds.

Cartesian

The ICS provides a complete system solution! The ICS usually consists of various combinations of the ISP or ISPD (Clean Room) high-performance actuators which feature exceptional speed, rigidity, repeatability, and payload capabilities. Additional possible combinations include those using Robo Cylinders, IF, and other series actuators.

An ICS is a complete system, including the high-performance X-SEL motion controller and all necessary brackets, cables, and cable management. Various communication options available on the X-SEL controller ensure smooth integration.

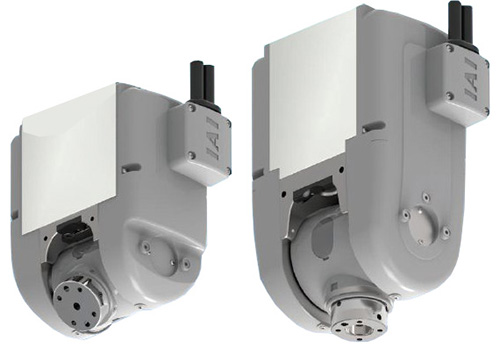

WU Series - 2 AXIS Wrist Units

IAI's Unique WU Series Wrist Unit design makes it light weight and compact in size.

Equipped with a battery-less absolute encoder as standard, the WU Series is a low cost alternative, compared to 6-axis articulated robots making it ideal for reducing the cost of equipment.

Diagonal approaches and tip swiveling can now be performed with minimum required axis configuration which until now required a vertically articulated robot.

- Unique design makes the parts light and compact

- Ideal for reducing the cost of equipment

- Orthogonal axes and interpolation commands are possible

IK Series Multi-Axis Cartesian System

The competitively priced ROBO Cylinder IK Series is the multi-axes solution to your automation needs. In addition to easy set-up and simple software programming, IAI's high-quality electric actuators are energy efficient and will dramatically reduce your energy bills.

The ROBO Cylinder IK Series multi-axes kit includes everything needed for fast and easy assembly. The available configurations have been greatly expanded, allowing the ideal selection to suit your needs from 396 options. The ROBO Cylinder® equipped as standard with a Battery-less Absolute Encoder has been added to the "IK Series".

No battery maintenance is required since there is no battery. Homing operation is not required at startup or after emergency stop or malfunction. This reduces your operation time, resulting in reduced production costs.

Compatible with PowerCON® which is equipped with a high-output driver. The maximum speed has been increased with the use of PowerCON®. This can reduce cycle time and help improve productivity.

High Speed Actuators

Shortening production equipment cycle times

By adopting a high-speed actuator, you will be able to shorten your production equipment cycle time, improving your equipment's production capacity.

IAI's lineup of high-speed actuators come in four driving systems: ball screw drive, ball screw nut rotating drive, belt drive, and linear motor type. There is a total of 69 types in 12 series with maximum speed of over 2,000mm/s. you can choose the most suitable one to meet your needs.

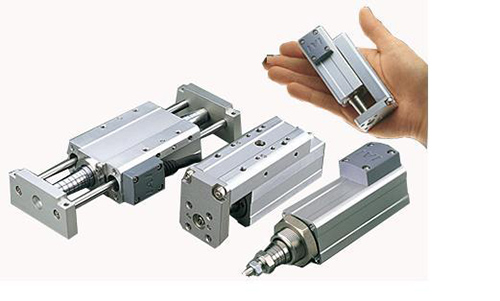

Mini ROBO Cylinders

Shaped like an air cylinder and easy to use the Mini-ROBO Cylinder has achieved smaller size with significantly reduced overall length, width and height which are comparable to air cylinders. Systems that could only use air cylinders due to sizing constraints can now use Mini ROBO Cylinders to improve performance.

If you have been using air cylinders and are unhappy with the long time needed to change the positions or want to stop the actuator between two points, you can adopt a ROBO Cylinder system and continue it with PSEP/ASEP controller. Users who are comfortable with the handling of pneumatic systems are now able to switch to ROBO Cylinder effortlessly.

- Slider type, Rod type

- Table top

- Linear servo type

- Guided and Non-guided

Tabletop Robots

Quickly deployable TTA tabletop robots from IAI are precise positioning and assembly platforms with working areas between 200 x 200 mm and 500 x 500 mm. Customers particularly appreciate the rapid operational readiness without mechanical effort from this IAI robotics solution. All models are equipped with battery-less absolute encoder as standard. A new high-precision AC servo motor series has been added.

IAI - Motorized Vertical Grippers

IAI's Vertical grippers are available in two types, including the slider type that comes with a guide to achieve excellent rigidity, and the lever type whose levers open by 180 degrees for easy gripping of the work part.

Slider Type and Lever Type Grippers

Vertical grippers are available in two types, including the slider type that comes with a guide to achieve excellent rigidity, and the lever type whose levers open by 180 degrees for easy gripping of the work part.

Multi-point Positioning, Adjustable Gripping Force

Up to 512 positioning points are supported via servo control, and the force with which to grip the work part is adjustable. This makes it possible to adjust the finger opening/closing width and grip easy-to-deform work parts.

Highly Rigid, Accurate Guide and Driving Part

The slider type comes with a highly rigid linear guide to demonstrate high moment rigidity. Thanks to its backlash eliminating mechanism, the guide is subject to less displacement upon positioning. The driving part adopts a geared structure (worm + helical gears) to achieve high rigidity and excellent response.

Self-locking Mechanism to Prevent Parts Dropping upon Power Off

The self-locking mechanism prevents the work part from dropping when the power is turned off or an emergency stop is actuated. The slider and levers can be opened with ease using an Allen wrench. * The actuator cannot be kept pushing the work part.

Ultra-compact Slider Type

High gripping force in a compact body (gripping force: 10 N). One of the smallest actuators in the industry with a cross section area of 22 x 15 mm.

RCS3 Servo Press

The RCS3 Servo Press is a compact and low-thrust rod type IAI actuator that can even be used for simple pressing. The high-precision position control enables easy adjustment of the push force and the position control. The IAI servo press specification has been expanded. With a load cell equipped as a standard feature, precision push force control is now possible, which is typically difficult for oil-hydraulic equipment.