Hose Master

Hose Master is a company that specializes in the manufacturing of custom designed metal hoses tailored to meet the specific needs of customers. Hose Master is known for reliable engineering, manufacturing of high quality hose products and accessories including; flexible metal hoses and expansion joints, corrugated metal hoses, stripwound metal hoses and flex connectors. Hose Master is committed to supplying world class metal products which stand up to extreme temperatures, high pressures and harsh chemicals. Wherever and whenever needed.

Products

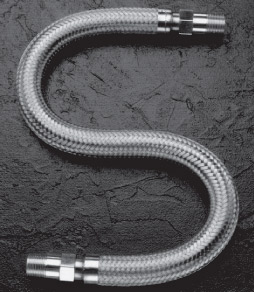

Corrugated Metal Hose

Corrugated metal hose can handle high pressures and is gas tight. It is excellent for gas and liquid transfers.

Annuflex

High-performance annular corrugated stainless steel hose

Masterflex

With an increased number of corrugations per foot for greater flexibility

Formflex

Provides stress-free connections between piping systems and rotary joints

Pressureflex

Heavy-wall specifically designed for higher pressure applications

PressureMax HP

For ULTRA high pressure applications

ChemKing

Chemical transfer hydroformed hose offers excellent corrosion resistance

Bronzeflex

For applications that require bronze hose

Hydraflex

Double walled, spirally-welded helical corrugated hose

Extraflex

Designed to achieve extreme flexibility while maintaining good pressure rating

Stripwound Metal Hose

Stripwound metal hose, although not gas tight, is rugged, making it excellent for use as a guard, an open-ended exhaust hose, and for the transfer of dry bulk materials.

Interflex

High-quality general-purpose metal hose

Interflex .030

Used to convey air, exhaust

Flow-Tite

Patented fitting system designed for leak resistance and smooth product flow

Tar and Asphalt

Used for the transfer of high temperature viscus fluids

Ultraflex

Smoothbore metal hose for dry bulk pneumatic conveyance

FloppyGuard

Superior flexibility and crush-resistant contruction

T-Rex

The first torque-resistant stripwound metal hose with enhanced sealability.

Solutions

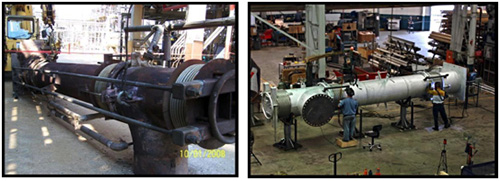

Expansion Joints

Designing the right expansion joint for mission critical applications can be intimidating.

Our state-of-the-art manufacturing facility and proprietary equipment ensure that the expansion joints are made right - the first time.

FireShield Petroleum Systems

Hose Master's Fire-Shield connectors are the safest, longest lasting, and most flexible metal hose connectors manufactured today. Hose Master's unique "hydroforming" process makes the difference by minimizing residual stress points created in the hose during the manufacturing process. Hose Master's proprietary tube seam weld technology resists aromatic vapor permeation and Hose Master's precise ASME certified welders follow specified procedures to insure the strongest fitting attachments.

Hose Master's extensive array of available end fittings offer the quickest and most cost-effective solutions for connecting fiberglass or flexible pipe to the submersible pump and shear valve. Hose Master's Fire-Shield connectors minimize threaded connections, which means fewer leak points and reduced installation time and labor.

Hose Master's Fire-Shield connectors meet all specifications for aboveground and underground piping applications, and comply with NFPA and UFC codes. They are rated for full vacuum and are available with BSPP and BSPT threaded fittings. Connectors are designed to accept approved secondary containment systems.

Make the Most of Your Maintenance Budget with Refurbished Expansion Joints from Hose Master

Refurbished expansion joints from Hose Master are cost-effective solutions that not only save money, but offer opportunities to improve function and service life.

Hose Master refurbishes large diameter expansion joints that have been removed from service. By reconditioning the components, like pipe and fittings, and replacing the bellows, Hose Master can completely overhaul an existing expansion joint at a significantly lower cost than creating a replacement.

In addition, Hose Master's staff of engineers provide design recommendations that can be implemented to modernize the expansion joint for better function and service life. These recommendations reduce the complexity of the repairs as well as minimize future repair expenses.

Refurbishing Expansion Joints

- Decreases Turn-Around Time

- Decreases Cost

Contact Air Hydro Power today for cost effective expansion joint refurbishing solutions.